Description

| Performance chart for avika series, self priming monobloc pumps, at rated speed, 50hz frequency, three phase a.c power supply | |||||||||||||||||||

| S.No. | Pump Model | Power Rating | Pump Size (MM) | Impeller Dia (MM) | Rated Voltage (Volts) | Solid Handling Size (MM) |

RATED SPEED (RPM) |

Total Head in Meters | |||||||||||

| 6 | 8 | 10 | 12 | 14 | 15 | 18 | 20 | 22 | 24 | ||||||||||

| KW | HP | SUC. | DEL. |

Discharge in Litres Per Second |

|||||||||||||||

| 1 | A1-05M | 0.37 | 0.5 | 40 | 40 | 116 | 210/415 | 5 | 2700 | 3.1 | 2.6 | 2.1 | 1.2 | – | – | – | – | – | – |

| 2 | A1-0M | 0.75 | 1 | 40 | 40 | 116 | 210/415 | 7 | 2700 | 4.4 | 4.0 | 3.2 | 2.3 | 1.0 | – | – | – | – | – |

| 3 | A1-1HM | 1.5 | 2 | 40 | 40 | 134 | 415 | 8.5 | 2800 | – | – | 5.9 | 5.1 | 4.2 | 3.1 | 1.5 | – | – | – |

| 4 | A1-2HM | 2.2 | 3 | 50 | 50 | 145 | 415 | 10.5 | 2800 | – | – | 8.7 | 8.2 | 7.4 | 6.5 | 5.5 | 4.3 | 3.0 | 1.0 |

| 5 | A1-3LM+ | 3.7 | 5 | 80 | 80 | 224 | 415 | 15.5 | 1420 | – | – | 17.5 | 15.5 | 12.5 | 8.0 | 3.5 | – | – | – |

Note:- A1 05m and a10m are supplied with mechanical seal arrangement and also available in signal phase.

All other models are supplied with stuffing box arrangement for gland packed or mechanical seal as per the requirement.

|

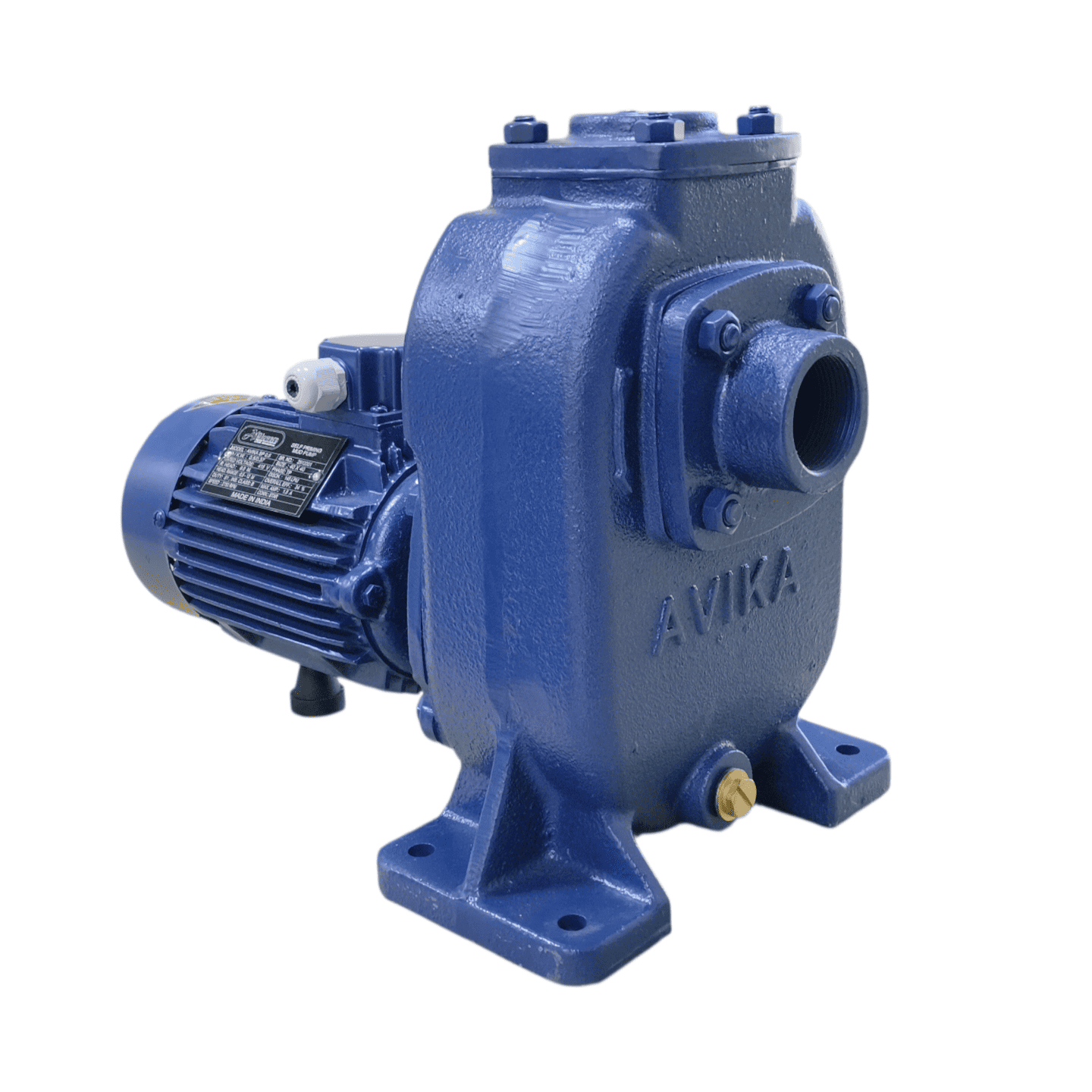

Technical Specification |

|

| A1 Monobloc | |

|

Head Range |

UPTO 24 METRES |

| Discharge Range | UPTO 17.5 IPS |

| Power Rating | 0.37 – 3.7 KW (0.5-5 HP) |

| Voltage Range | 300-400V (THREE PHASE) 180-240V (SINGLE PHASE) |

| Class of Insulation | B/F CLASS |

| Protection | IP 44 / IP 55 |

|

Material of Construction |

|

| A1 Monobloc | |

|

Impeller |

Cast Iron / Stainless Steel / Bronze |

| Motor Body | Cast Iron |

| Delivery Casing | Cast Iron |

| Shaft | Carbon Steel / Stainless Steel |

| Shaft Sleeve | Stainless Steel (Bronze -A1-3lm+) |

| Sealing | Gland Packed / Mechanical Seal |

FEATURES

- Self Priming : No need of foot valve and priming pump set every time for quicker operations.

- Non Clog Impeller : Non clog impeller to handle suspended soft solids up to 60 mm in size made it suitable for sewage and dewatering applications.

- Flatter Efficiency Curve : Minimum variations in efficiency during entire operating range increases the utility of pump set for variable conditions.

- Designed To Prevent Overloading : Lesser chances of motor burning as the motor does not get overloaded even if the pump is operated at a head lower than recommended, thus ensuring substantial cost savings due to low maintenance and breakdown.

- Dynamically Balanced Rotating Parts : Minimum vibrations protect components from damages during the operations, thus ensuring consistent performance as concentricity is maintained.

- Replaceable Wearing Parts : All wearing parts within the pumps are easily accessible and replaceable which facilitates ease of maintenance thereby extending the life of the pump.

- Easy Maintainable Designs : Easy maintainable design and better interchangeability of components so that pump can be serviced even at remote locations by semi-skilled technicians.

Reviews

There are no reviews yet.