Description

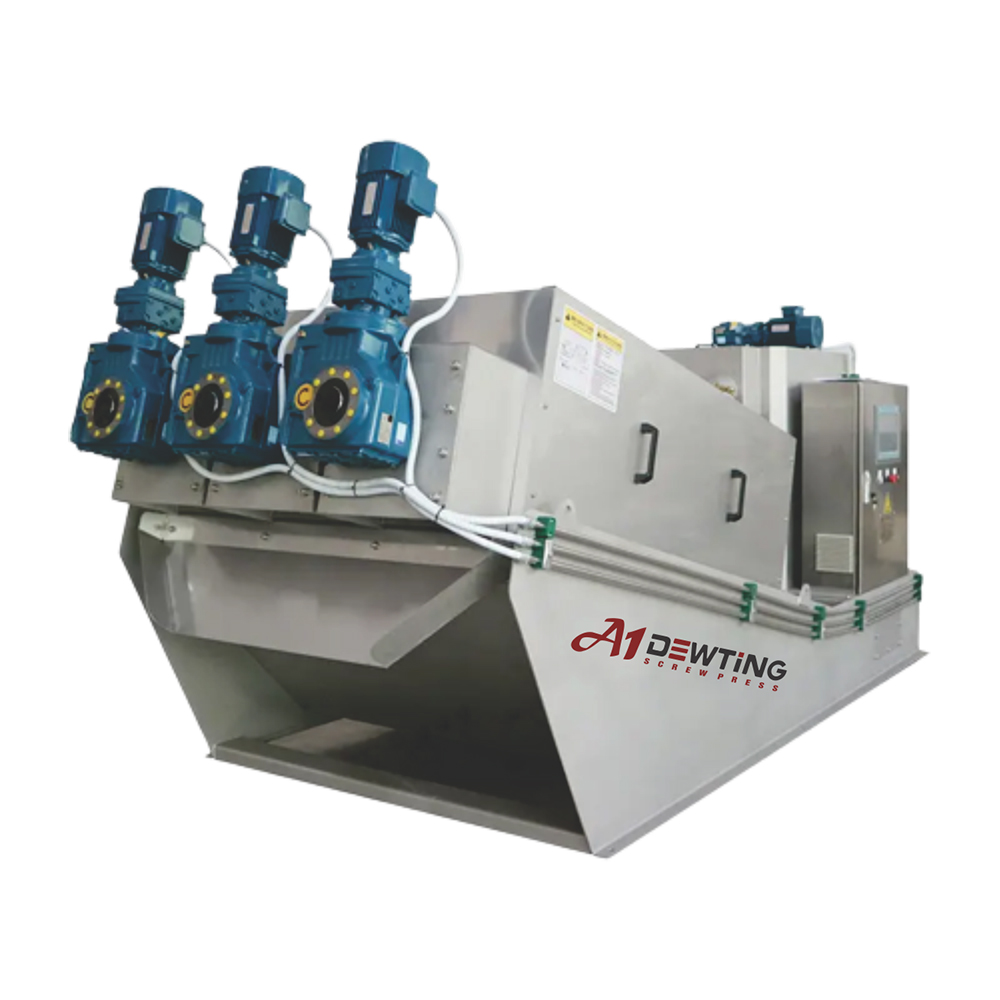

Sludge De – Watering Machine With Multi Disk Screw Press

A1 BLOWERS leading manufacturer of Roots Blowers, Now we are introduces our new product Sludge De- Watering Machine Multi Disk Screw Press.

Multi-disc Screw Press Sludge Dewatering Machine, it’s clog-free and can reduce the sedimentation tank and sludge thickening tank, saving the cost of sewage plant construction. Using screw and the moving rings to clean itself as clog-free structure, and controlled by the PLC automatically, it’s a new technology that can replace the traditional filter press, centrifuges, belt press and frame press, the screw speed is very low, so it cost low power and water consumption in contrast to the centrifuge, it is a cutting edge sludge dewatering machine.

About Screw Press:

Sludge water is a product of mechanical, biological and chemical treatment of wastewater in wastewater treatment plants, food and chemical industries and other sectors of human activity. Our dewatering screw press is used to thicken sludge water to 20% dry-matter content. In terms of quality, this equipment surpasses traditional sedimentation sludge removal and other dewatering technologies.

This dewatering/thickening screw press has been designed to be used primarily in wastewater treatment plants, but can also be used for thickening both industrial water and wastewater in food processing operations.

If a dewatering press is already incorporated into the new WWTP design, costs related to the construction of sedimentation tanks are eliminated as this equipment can also be used for thickening secondary sludge directly from activation.

Features:

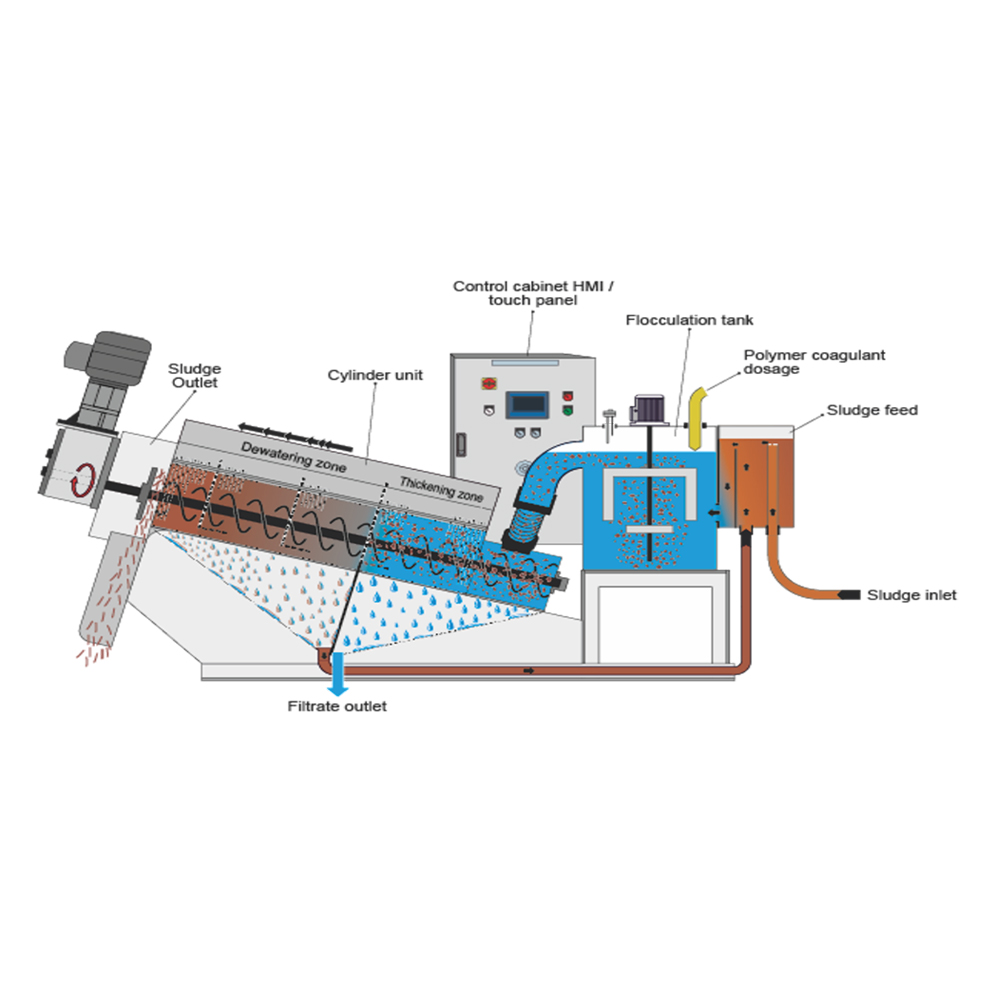

Flow Control Tank :- Feeds a fixed amount of sludge to the flocculation lank whilst the excess sludge returns to the storage tank.

Flocculation Tank :- A Polymer is mixed with the sludge to form flocks suitable for the Volute.

Thickening Zone in cylinder unit:- The sludge enters the thickening zone, and the initial filtrate is discharged whilst the thickened sludge is pushed towards the dewatering zone by the screw.

Dewatering Zone :- In the section the gape between the rings and the screw pitch decrease gradually in the direction of the end plate, whilst the pressure of the filter element increases due to the volume compression effect, which thickens and dewaters the sludge.

End Plate:- The end plate creates further pressure from the outlet side so that the sludge becomes drier, resulting in an up to 35% solid sludge cake which is released from the sludge cake outlet.

SALIENT FEATURES

- Extremely Low energy consumption.

- No requirement of Thickener or drying beds.

- Clog-Free & small foot print.

- Fully automatic control.

- High resistance to oily sludge.

- Lesser Manpower requirement.

- Very Low water requirement for washing.

- Less Noise, less odour.

Technical Data Sheet

| Model | Dry Sludge (Kg/hr) | Inlet Flow @ 1% Conc. | Electrical Load (KW) | Dimension in MW | Rinsing Water (L/hr) | ||

| A1-DWM 0.5 | 2-5 Kg/hr | 0.5 m3/hr | 0.36 | 1500 | 710 | 950 | 30 |

| A1-DWM 1.0 | 5-10 Kg/hr | 1.0 m3/hr | 0.36 | 1900 | 700 | 1000 | 40 |

| A1-DWM 1.5 | 10-15 Kg/hr | 1.5 m3/hr | 0.36 | 2100 | 800 | 1000 | 50 |

| A1-DWM 2.0 | 15-20 Kg/hr | 2.0 m3/hr | 0.54 | 2300 | 900 | 1250 | 60 |

| A1-DWM 3.0 | 20-30 Kg/hr | 3.0 m3/hr | 0.55 | 3000 | 900 | 1200 | 80 |

| A1-DWM 4.0 | 30-40 Kg/hr | 4.0 m3/hr | 0.55 | 3050 | 900 | 1300 | 100 |

| A1-DWM 6.0 | 40-60 Kg/hr | 6.0 m3/hr | 0.92 | 3100 | 950 | 1600 | 150 |

| A1-DWM 10 | 70-100 Kg/hr | 10.0 m3/hr | 1.25 | 3200 | 1000 | 1650 | 200 |

| A1-DWM 15 | 120-150 Kg/hr | 15.0 m3/hr | 1.30 | 3400 | 1100 | 1650 | 250 |

| A1-DWM 20 | 160-200 Kg/hr | 20.0 m3/hr | 1.47 | 4100 | 1100 | 2200 | 300 |

| A1-DWM 25 | 200-250 Kg/hr | 25.0 m3/hr | 1.87 | 4100 | 1100 | 2200 | 350 |

| A1-DWM 30 | 250-300 Kg/hr | 30.0 m3/hr | 2.75 | 4000 | 1500 | 2130 | 450 |

| A1-DWM 40 | 300-400 Kg/hr | 40.0 m3/hr | 2.95 | 4300 | 1500 | 2200 | 600 |

| A1-DWM 50 | 410-500 Kg/hr | 50.0 m3/hr | 3.75 | 4400 | 1500 | 2200 | 700 |

Note: Due to continuous Research & Development specifications may change without any notice.

APPLICATIONS

- Domestic & Munciple STP

- Food & Beverages

- Slaughter Breeding

- Printing & Dyeing

- Chemical Industries

- Oil Industries

- paper & Pulp

- Petrochemical Etc.

Reviews

There are no reviews yet.